Tubes for automotive applications

Vehicles – for sure!

Passenger safety, topics such as lightweight construction and sustainability: We constantly develop our steel grades together with you, thereby guaranteeing maximum strength, low weight and value optimization along your entire value chain. And what's more, we help you achieve your sustainability goals with innovative steel products. The result is innovative tube solutions, using the latest technology, that are designed to fufil the requirements of the end product. Whether seamless or welded.

Together, we make mobility lighter, safer and more sustainable.

Longer vehicle range, lower fuel consumption? Yes, you can. With our lighter tube solutions, savings of up to 40 % in component weight are possible. For example, anti-roll bars made of high-strength materials with correspondingly reduced or variable wall thicknesses. Just one of many examples with which we make your mobility lighter, safer and more sustainable.

Many products, many solutions

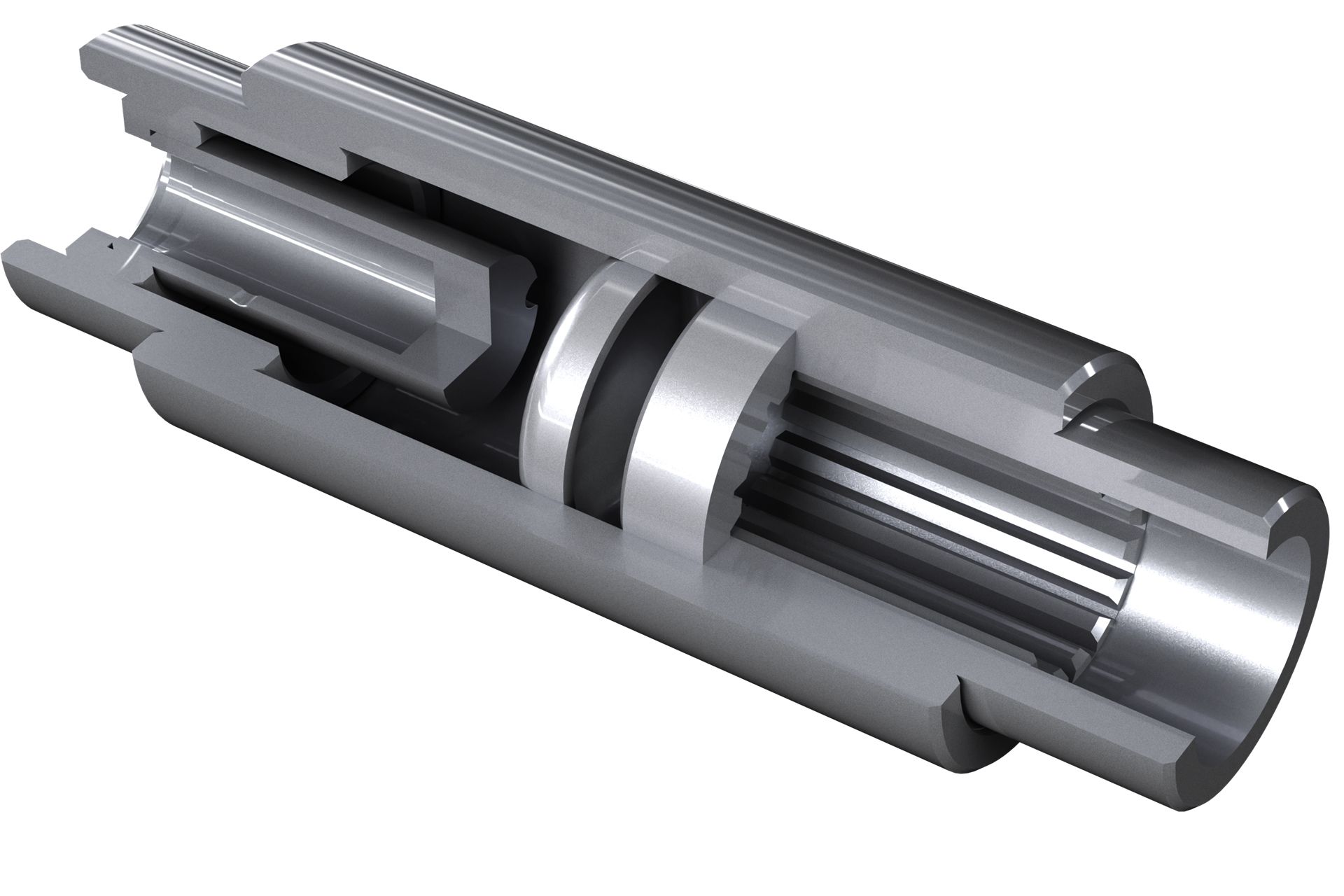

Rotor shafts

Lightweights that take a heavy load

Rotor shafts made from tube save a considerable amount of material and with it, weight. That’s an important aspect, especially when it comes to electric vehicles. Because weight reduction through lightweight construction contributes to a higher range of the vehicles. Rotor shafts made from our welded or seamless drawn precision steel tubes are light, safe and equally robust. Even at speeds of up to 30,000 rpm.

Fluid routing lines

For tight spaces and tight connections

Our precision steel tubes can be formed to meet demanding requirements. As a result, they fit into tight spaces and ensure tight connections. Innovative coatings such as Zistaplex offer optimum protection against corrosion. All without chrome VI. Even with subsequent machining and extreme deformation.

Prop shafts

Maximum precision for completely smooth running

Drive shafts require high strength, high precision and good surface properties. With their optimized geometric properties and high dimensional accuracy, our precision tubes ensure the lowest possible drive shaft imbalance. And also guarantee extremely small and constant differences in length during forming processes such as rotary swaging.

Steering

Top quality, easily processed

Homogeneous microstructure, good surface quality, best forming properties: these are the impressive features of our tube products for steering applications. This makes additional processing very easy. If you require, we can also supply our tubes with an inner profile.

Seat belt tensioners

Optimal for bending and flaring

Our precision steel tubes guarantee the tightest tolerances on external and internal diameters. Thanks to their mechanical-technological properties, they can be excellently bent and flared. Our optimized production process ensures significantly better surfaces. Also good to know: Modified carbon steels guarantee optimum flow behavior in later processing steps.

Airbag generator sleeves

Ready for installation

Capable of withstanding several thousand bar, our airbag generator sleeves are extremely resilient. In addition, we manufacture tubes from high-strength and low-temperature steels in fixed lengths with tight tolerances. Even at temperatures well below zero, the airbag systems function perfectly.

Axle solutions made from tube

High strength with good formability

The demands on tubes for axle applications are increasing. Ever tighter available space calls for increasingly complex forming processes. Our material concepts are tailor-made for this. High-strength micro-alloyed and air-hardening steels also reduce the weight of the components.

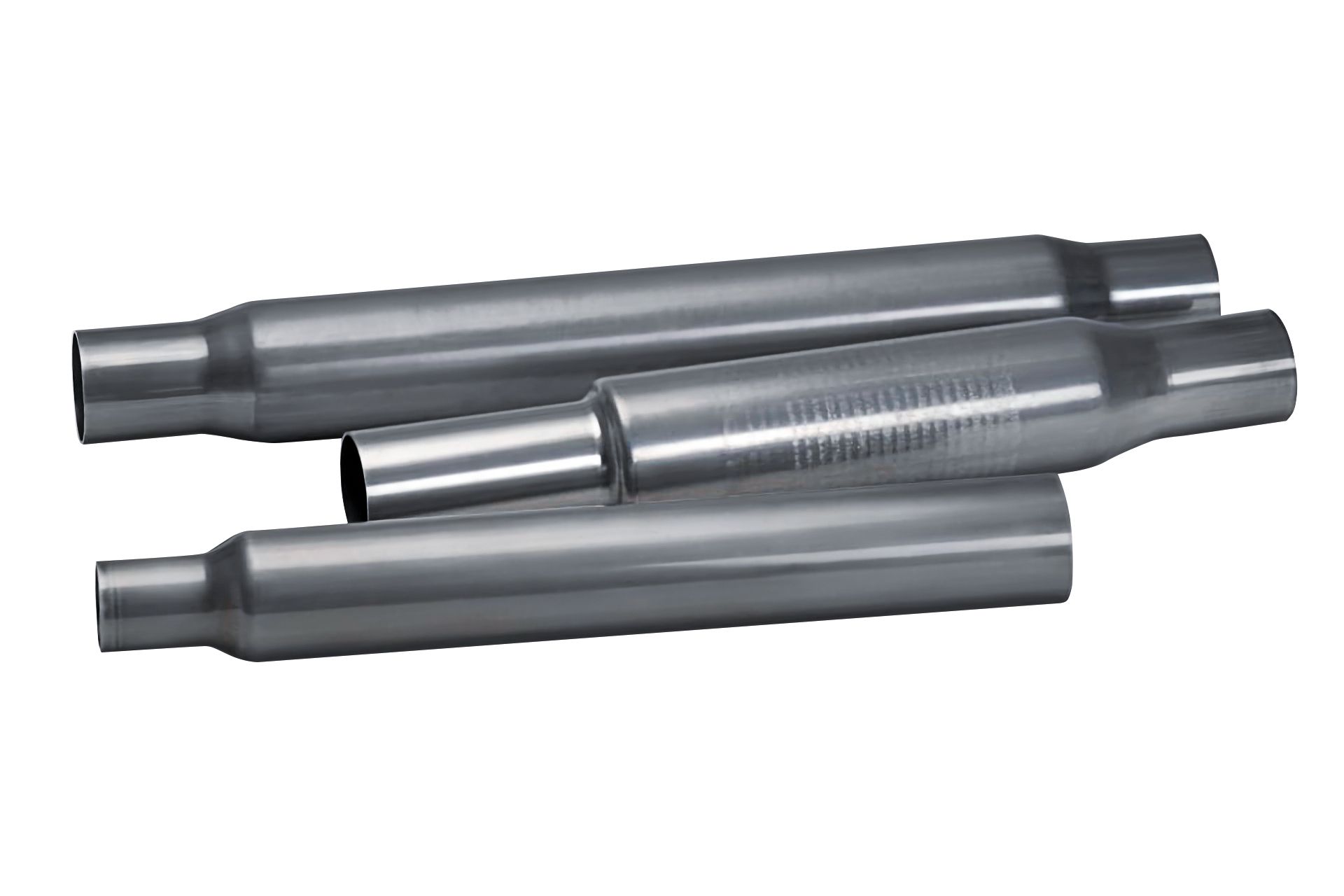

Gas springs

Ideal for lightweight construction

Faultless operation and long service life – a must in gas spring products. Our precision tubes for gas springs meet these expectations safely and reliably thanks to their excellent surface quality. Their homogeneous microstructure and tight tolerances ensure high process reliability in further processing.

Drive shafts

Particularly light and torsion-resistant

Drive shafts based on our tubes are light because we substitute solid material. The good surface finish and low edge decarburization make our steel tubes torsion-resistant. Their low eccentricity comes from a uniform wall thickness, which allows them to be formed efficiently – hot or cold.

Stabilizers

Our tubes are extremely robust

Our steel tubes can withstand even extreme forces. Thanks to their particular strength, our thin-walled tube solutions for chassis applications are ideal for replacing solid materials. High-strength steels offer significant weight savings. In addition, high carbon steels and minimized edge decarburization increase service life.

Machined products

Tubes made from free cutting steel

BENTELER SMARTCUT® tube made from free cutting steel is an innovative game changer wherever machined products are needed. This unique seamless tube solution reduces the machining requirements and waste associated with solid bar. Its elevated sulphur content allows increased machining speeds, larger cuts, and longer tool life compared to standard steel tubes. It’s also guaranteed lead free in line with the EU REACH regulation.