STEEL/TUBE Products

Excellence through solution competence

We know how to form and join metals like no-one else. At the same time, we like to think ahead. Future topics, megatrends and a constant dialogue with our customers – they all feed into the development and production of our steel and our quality seamless and welded tubes. This gives our tube products a performance profile that corresponds exactly to your requirements, so you always get the optimal product for your applications. Tailor-made, optimized for further processing and just-in-time. You can count on it.

Steel products for tomorrow

Sustainability is part of our corporate strategy. Which is why we constantly develop our steel products to not only meet market standards, but to stay ahead of them. We are already working on a climate-neutral future – with high-quality steel from our electric steel mill where we already turn recycled scrap into top-quality CliMore steel. For up to 75% less CO2 emissions. With green electricity it’s even less! Doing more with less emissions — that's the future. LEARN MORE

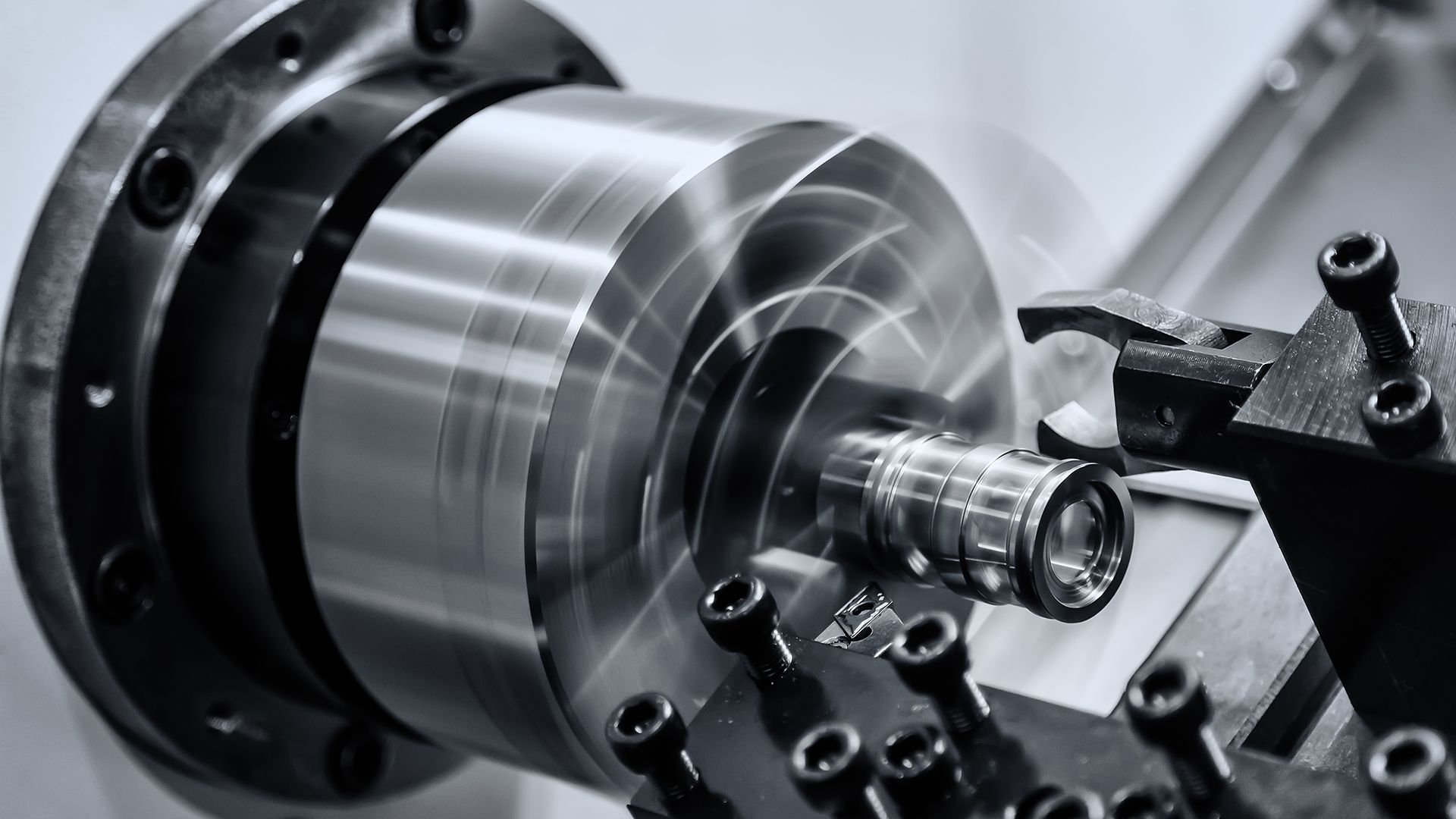

Special tube solutions that deliver high performance

Can you do more with less?

With BENTELER SMARTCUT® you can. Better for the environment, better for your bottom line, our innovative tube made from free cutting steel is the smart alternative to machining components from solid bar. This unique solution helps you significantly reduce your material, processing and manufacturing costs while increasing productivity.

Can corrosion protection also be environmentally compatible?

Take Zista® Seal, a product from our Zista® product family as an example. The organic sealant protects tubes from corrosion – even after forming. And all without chrome VI. It therefore complies with the European REACh regulation as well our goals for environmental protection.

How do we bring safety to the road?

Our precision fork tubes withstand high loads and don’t become brittle, ensuring reliability in the front suspension fork. And the comfortable damping makes the driving experience even more enjoyable. Strong and comfortable on the road – BENTELER makes it happen.

Our products at a glance

Agricultural machinery, power stations, drilling rigs for oil production: Our seamless hot rolled steel tubes and seamless cold drawn precision steel tubes are ideal for complex applications.

Dimensions:

- Seamless hot rolled steel tubes – size range: 21.3 to 164.5 mm

- Seamless cold drawn precision steel tubes – size range: 4 to 160 mm

Whether it’s for passenger cars, commercial vehicles or racing cars, we develop and produce welded and welded drawn precision steel tubes for you. For the highest demands, for example in passenger safety. Or as a lightweight solution for reducing emissions.

For automotive, energy, mechanical engineering or construction. Our extensive range of products complies with all relevant standards (DIN, EN, ASTM, API, etc.) as well as various industry and customer-specific regulations. Get in touch with us: We’ll find the right steel for your requirements.